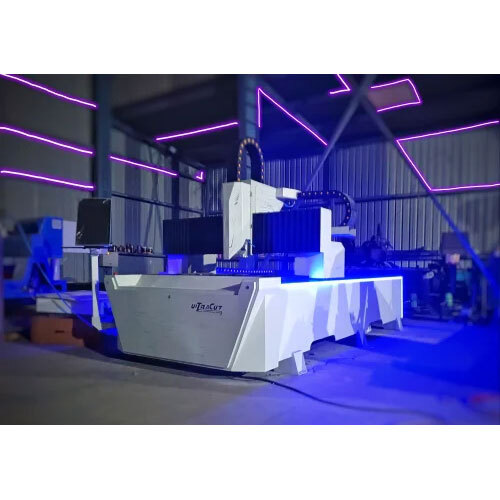

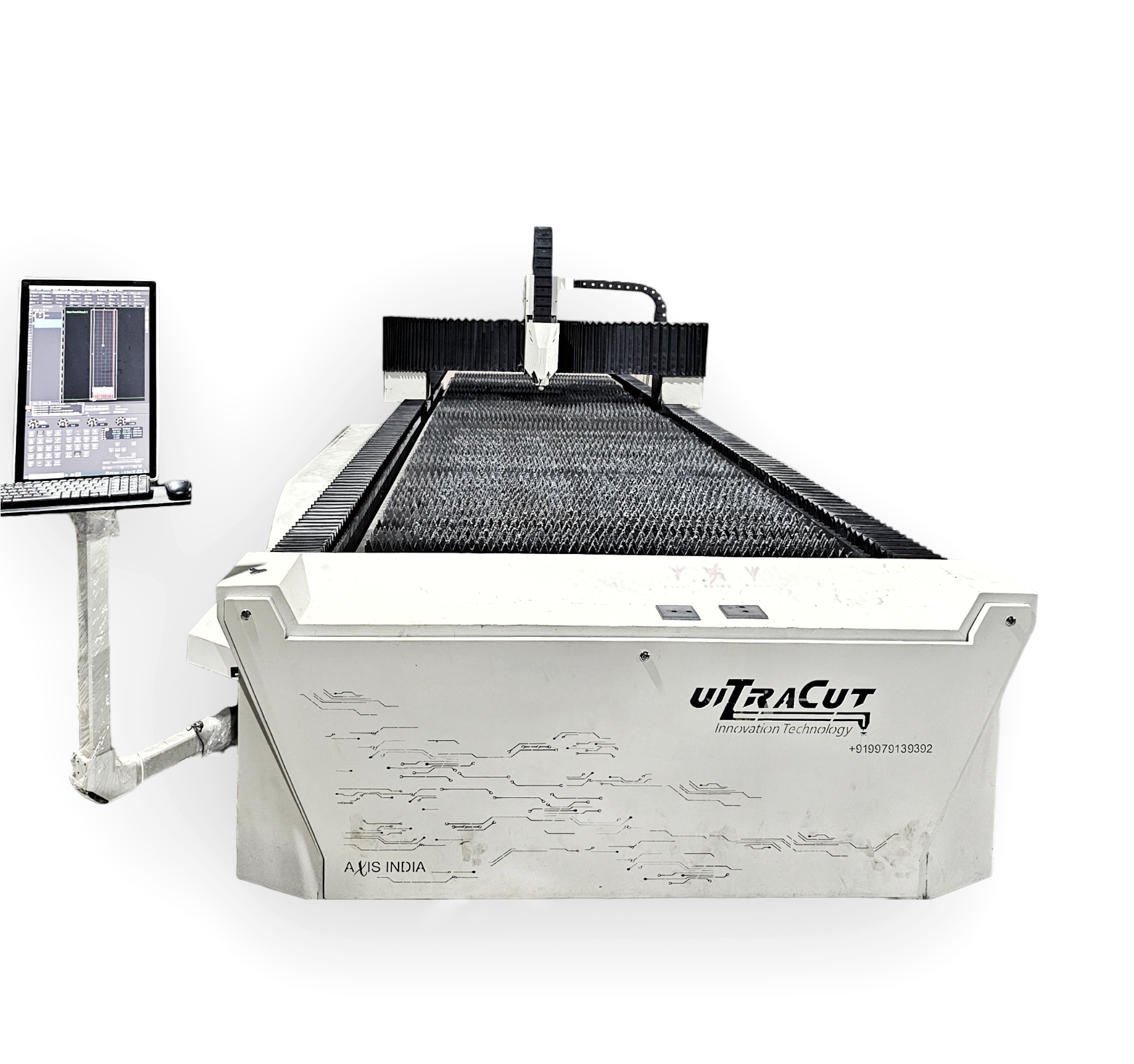

1000 Watt CNC Laser Metal Cutting Machine

Product Details:

- Product Type metal

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 0-12 Millimeter (mm)

- Cutting Area 1550*3100 Square Millimeter (mm2)

- Cutting Speed 0-100 m/m

- CNC Or Not CNC

- Click to view more

1000 Watt CNC Laser Metal Cutting Machine Price And Quantity

- 1 Unit

1000 Watt CNC Laser Metal Cutting Machine Product Specifications

- 0-100 m/m

- Water Cooling

- Metal

- 170*92*72 Inch (in)

- 380 Volt (v)

- DXF

- Lower Energy Consumption High Efficiency

- Frequency Speed Control

- metal

- 1550*3100 Square Millimeter (mm2)

- Green

- CNC

- Automatic

- 0-12 Millimeter (mm)

- Fiber Laser

- Yes

- 2 Years

- Weihong

- 3500 Gram (g)

1000 Watt CNC Laser Metal Cutting Machine Trade Information

- Vadodara

- Cash in Advance (CID) Cheque

- 1 Unit Per Month

- 45 Days

- Yes

- Contact us for information regarding our sample policy

- Wooden Box Packaging

- Asia Australia Central America North America South America Eastern Europe Western Europe Middle East Africa

- All India

Product Description

1. High-performance laser device associated with stable operation system enables optimal cutting effects.

2. Perfect cooling, lubrication and dedusting systems ensure stable, efficient and durable performance of the

whole machine.

3. Single countertop make plates loading and unloading available during cutting, which improves the

processing eficiency.

4. Large-size closed enclosure improves dedusting effects and avoids optical pollution.

5. Automatic height-adjustment performance keeps constant focal length and stable cutting quality.

6. Gantry structure and inblock aluminum cast cross beam make the device highly rigid, stable and antiknock.

7. It could ut mental in various materials and realize excellent and stable cutting effects.

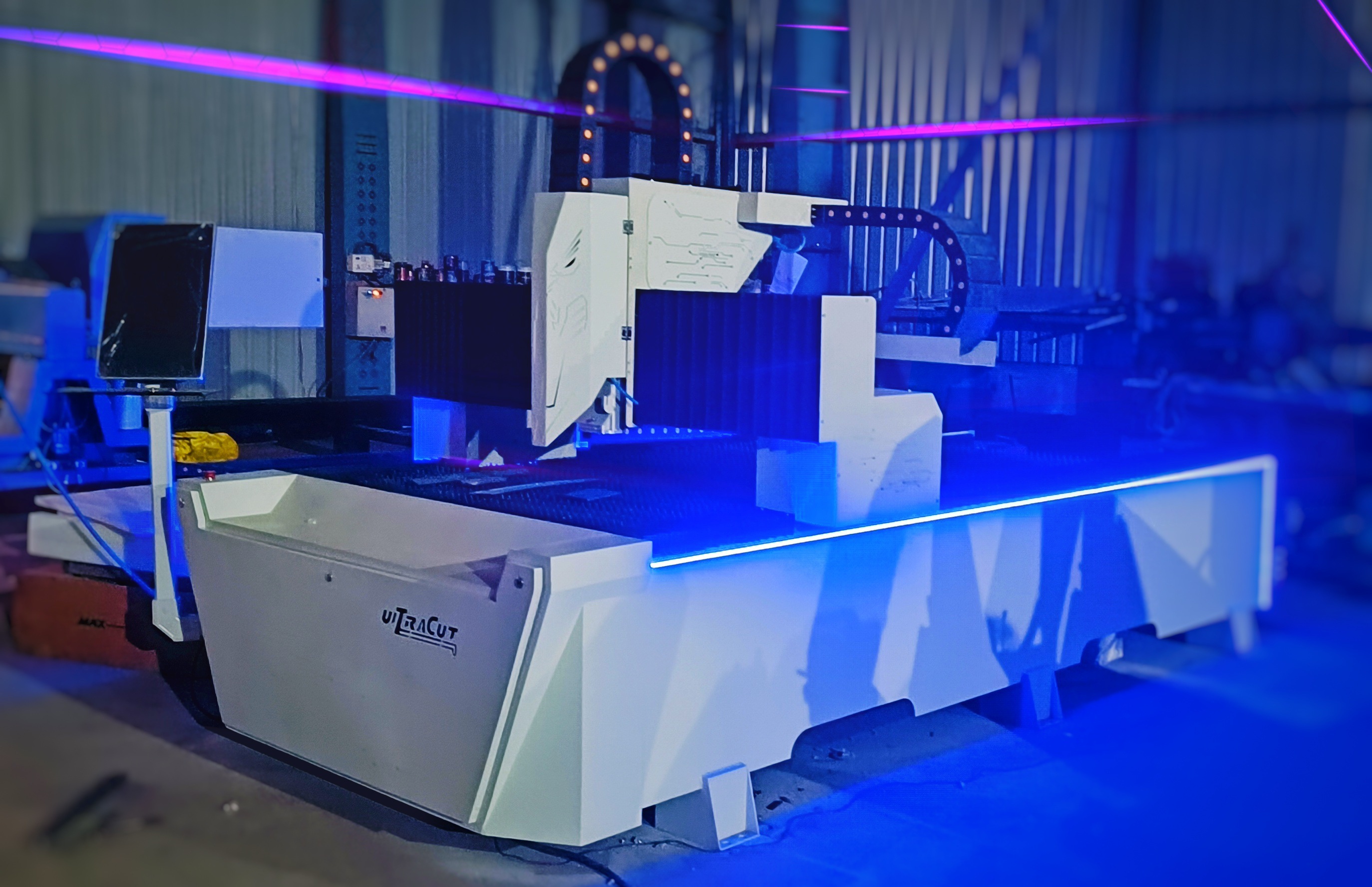

Characteristics of 1000w fiber metal cutting equipment

1.Great Performance

Identical cutting quality on any cutting point is realized through fiber transmission.

2.High Efficiency

The rapid cutting speed is two times higher than that of CO2 laser machine.Its use-cost is low.

3.Low Consumption of Gas

Laser cutting does not make any gas because of the specific cutting technology on steel plate.

4.Low Consumption of Energy

It is environment-protecting and energy-saving.Its power consumption is reduced by 20%-30% compared with that of CO2 laser machine.

5.Maintenance-free

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+