Welcome to our company

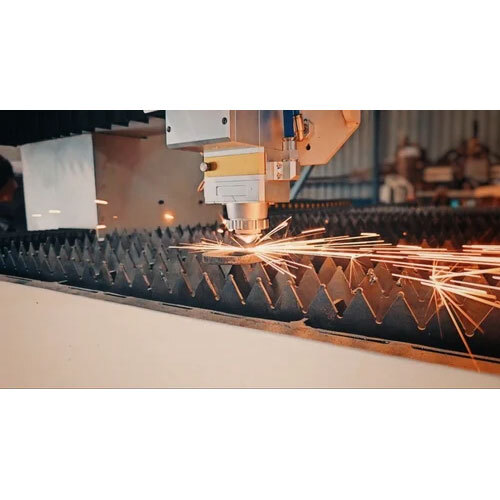

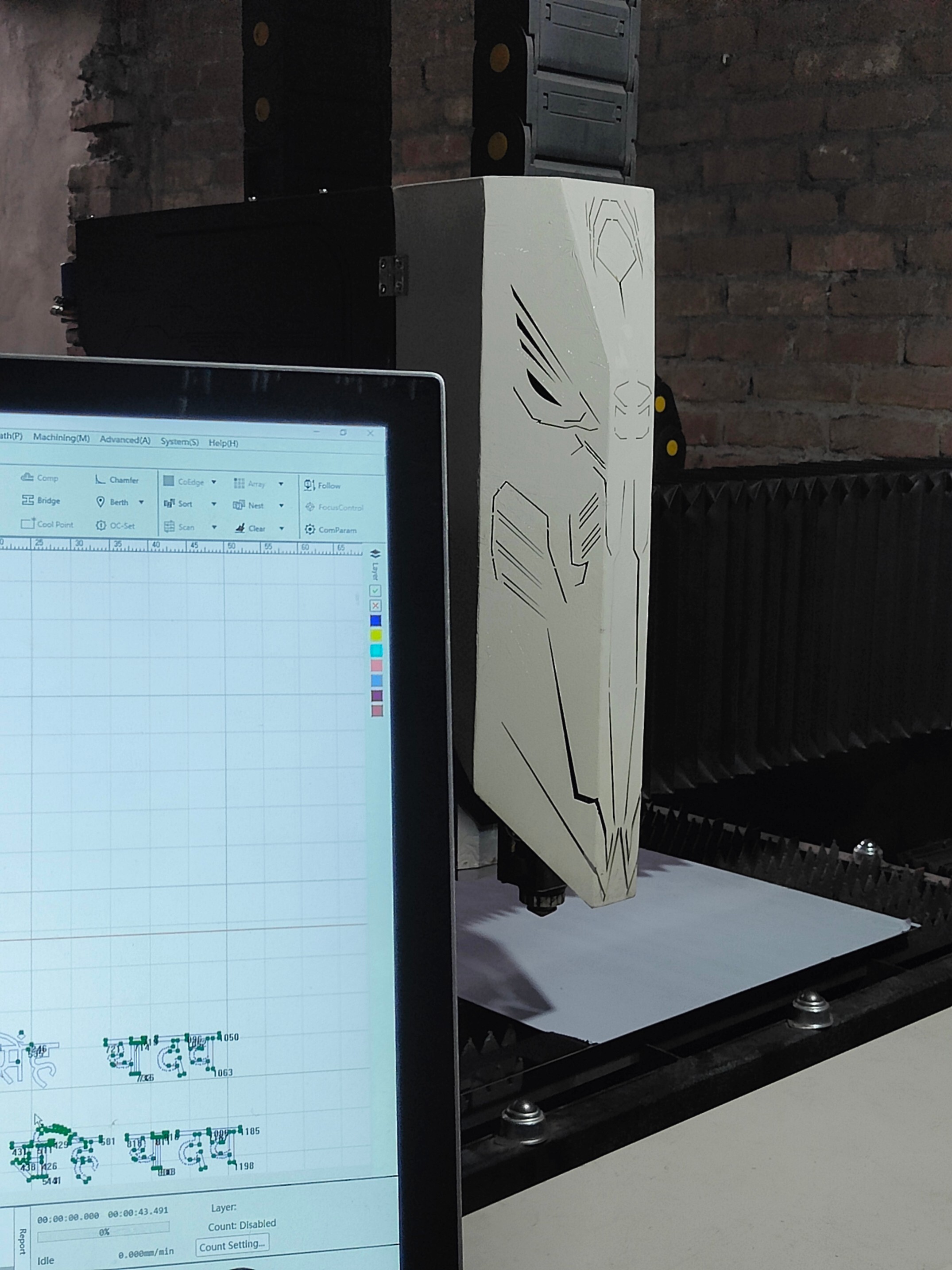

Fiber Laser Cutting Machines Metal Laser Cutting Machine Steel Cut Sheet Metal Raycus Fiber Laser

Product Details:

- Product Type Fiber Laser Cutting Machine

- Laser Type Fiber Laser

- Material Metal

- Cutting Thickness 0-12 Millimeter (mm)

- Cutting Area 1300mm*2600mm Square Millimeter (mm2)

- Cutting Speed 0-100 m/m

- CNC Or Not CNC

- Click to view more

X

Fiber Laser Cutting Machines Metal Laser Cutting Machine Steel Cut Sheet Metal Raycus Fiber Laser Price And Quantity

- 1 Unit

Fiber Laser Cutting Machines Metal Laser Cutting Machine Steel Cut Sheet Metal Raycus Fiber Laser Product Specifications

- Weihong

- 0-12 Millimeter (mm)

- 170*92*72 Inch (in)

- Yes

- Fiber Laser

- Metal

- 3.5 Tonne

- Lower Energy Consumption High Efficiency Low Noise

- Automatic

- DXF

- 0-100 m/m

- Water Cooling

- 2 Year

- White

- 220-440 Volt (v)

- Fiber Laser Cutting Machine

- Frequency Speed Control

- CNC

- 1300mm*2600mm Square Millimeter (mm2)

Fiber Laser Cutting Machines Metal Laser Cutting Machine Steel Cut Sheet Metal Raycus Fiber Laser Trade Information

- Vadodara

- Cash Advance (CA) Cash in Advance (CID) Cheque

- 4 Unit Per Month

- 45 Days

- Yes

- Asia

- All India

Product Description

CNC Fiber Laser Cutting Machine, which can be adapted based on your company™s capabilities and product goals at Ultracut Innovation Technology:

1. Laser Source

- Laser Power: 1kW to 12kW (adjustable based on the material type and thickness)

- Laser Type: Fiber laser

- Wavelength: 1070 nm

- Laser Brand: IPG / Raycus / nLIGHT / Maxphotonics (depending on cost and performance requirements)

- Expected Lifetime: 100,000 hours

2. Cutting Area

- Standard Models: 1500mm x 3000mm (5ft x 10ft)

- Optional Models: 2000mm x 4000mm, 2000mm x 6000mm, 2500mm x 8000mm

- Z-Axis Travel: 100mm “ 250mm (depending on material and part geometry)

3. Cutting Speed

- Mild Steel: 1mm thickness “ up to 60 m/min

- Stainless Steel: 1mm thickness “ up to 50 m/min

- Aluminum: 1mm thickness “ up to 45 m/min

- Copper and Brass: Thin sheets can be cut efficiently (power-dependent)

4. Maximum Material Thickness

- Mild Steel: up to 30mm

- Stainless Steel: up to 20mm

- Aluminum: up to 20mm

- Copper/Brass: up to 10mm (may require higher wattage for thicker cuts)

5. Positioning Accuracy

- Positioning Accuracy: ± 0.03mm

- Repeatability: ± 0.02mm

6. Drive System

- X, Y, Z Axes: Servo motors (high precision, fast response)

- Transmission: Rack and pinion or ball screw (depending on the application)

- Linear Guide: High precision linear guide (e.g., HIWIN, THK)

7. Control System

- CNC Controller: FSCUT2000/FSCUT3000 series, or Beckhoff, Siemens, or PA (based on regional availability)

- User Interface: Touchscreen panel with intuitive operation software

- Support: DXF, PLT, AI, and other standard formats

8. Auxiliary Equipment

- Automatic Focusing Cutting Head: e.g., Precitec, RayTools

- Cooling System: Water Chiller (sized based on laser power)

- Dust and Fume Extraction: Cyclone or downdraft table with air filtration systems

- Gas Supply: Nitrogen, oxygen, or compressed air (depends on material)

9. Power Supply

- Input Voltage: 380V, 50/60Hz, 3-phase (adjustable based on regional requirements)

- Power Consumption: Dependent on laser power (approximately 10kW for a 3kW laser)

10. Other Features

- Automation: Options for sheet loading and unloading, robotic arms for large-scale operations

- Safety: Fully enclosed or semi-enclosed models with protective glass

- Software: Nesting software, remote diagnostics, and real-time monitoring

11. Optional Features

- Pipe and Tube Cutting Attachment: For round, square, or rectangular tubes

- Auto Nozzle Changer: For seamless cutting operation with minimal downtime

- Material Thickness Detector: Automatically detects material thickness and adjusts parameters accordingly.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email